Sustainability

Biodiversity

Tree planting project

Recruit Group promotes activities to ensure the conservation of biodiversity, one of which is tree planting. The Matching & Solutions SBU has been involved in this activity since 2006, under joint funding with Recruit Holdings. As the circulation figures for our free newspapers/magazines grew and led to greater consumption of paper resources, we launched this activity in the context of corporate social responsibility, realizing that as a company dealing with paper media that if we consume trees we should also plant them as a way to give back to society.

Visit to the tree planting site

Tree trimming

Our tree farm stretches over 453 hectares across seven sites in North Perth, Western Australia. All farms have been certified by “Responsible Wood,” an Australian not-for-profit that sets globally recognised standards for managing forests sustainably and member of PEFC*1 International. The trees we plant are eucalyptus, which grow more than three meters a year, and can be harvested in ten years. Local staff from WAPRES (the largest tree plantation operator in Western Australia) , our partner for operations such as selecting land with good soil and introducing appropriate pest/weed control, which manage the tree plantations and regularly carry out regular upkeep.

Tree harvesting started in 2016 and the plan up to 2031 is to harvest wood chips amounting to 194,495 GMT (green ton: wet weight of wood chips including moisture). During the operation cycle, the cut/harvested trees are processed locally to produce wood chips, which are then delivered to paper manufacturers for use as raw material for paper production. We have acquired FSC*2 certification for this entire operation cycle.

We believe that running tree plantations will generate social and environmental value, and we plan to continue with this activity.

*1 PEFC stands for ”Programme for the Endorsement of Forest Certification.” It is an international non-profit, non-governmental global alliance which manages national forest certification systems around the world.

*2 FSC stands for “Forest Stewardship Council.”

Cooperation with suppliers to reduce environmental footprint in the papermaking and printing stages

Paper is a key raw material for magazines. When purchasing paper we look into the efforts made by suppliers to reduce environmental impact, examining their efforts in terms of the five practices below, which are of particular importance in the thinking of the Recruit Group. Together with our business partners, we intend to continue working together with our partners to further reduce their environmental footprint.

Eco-friendly materials procurement

Reduction in substances of concern, including CO2 and waste materials

Energy-saving, efficient manufacturing processes

Protection and growth of forest resources, a major raw material

Development and spread of green products

Smart distribution of free magazines

"Placing a large quantity of free magazines in a rack doesn't always increase the number of copies taken away. Necessary information needs to be optimally delivered to the people who need it. Distributing the appropriate number of copies contributes to Recruit Group's business, and is also useful as a resource preservation measure.

Recruit Group is conducting research on projects for improving distribution efficiency to reduce wasteful distribution, which has resulted in improving its accuracy. We call the ratio of the number of copies actually taken away to the number of copies placed in the rack the "takeaway ratio." The basis of improving the takeaway ratio is to plan the appropriate number of copies to be printed by determining how many copies are likely to be taken away as a whole. In addition, Recruit Group takes measures by analyzing the probability of the number of copies to be taken away from every single rack across the country, and devises a plan for the number of copies to be delivered and the delivery method for each of the rack types and layers. And recently, we've also used AI to improve the accuracy.

Paper recycling

Recruit Group also thoroughly collects and manages the remaindered free magazines in racks (remaindered copies). After the number of copies is reported by drivers in charge, most of them are collected by used paper companies and then delivered to paper-manufacturing companies. With such processes of recycling, the paper is recycled to cardboard and other paper based products.

Use of environmentally-friendly inks

When printing information magazines, we promote the use of environmentally-friendly inks and printing. Recruit Group uses environmentally-friendly "soy ink" in printing for 100% of the paper media periodically issued (except for annual magazines as well as covers, postcards, separate volumes, appendices, gravure printed materials, etc.). Soy ink generates fewer volatile organic compounds (VOCs), which are air pollutants, than ordinary inks do. In addition, we use "hardly fragmented hot melt (a kind of adhesive)," which is suitable for recycling, in binding for 98.5% of regularly issued paper media using perfect binding.

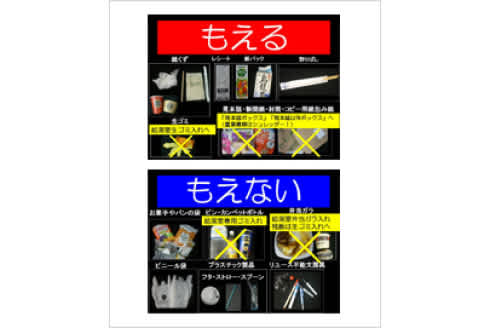

Disposal and recycling management

Most Recruit Group companies are tenants in buildings owned by others, and it is important that we work together with the building owners to strictly follow the trash separation rules established by local governments. In our headquarters offices in Gran Tokyo South Tower we separate trash for recycling on each floor. We have switched to signage that makes it a simple task for individual employees to separate trash for recycling. We also conduct educational activities in this area using our in-house communication tools. We will continue to separate trash for recycling as required by local governments in all our locations nationwide.